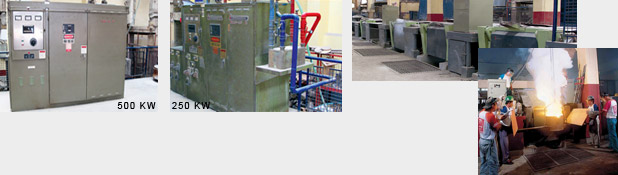

FACILITIES

|

|

|

|

|

|

|

PROPELLER CALCULATION |

|

SEA TRIAL |

|

PRE-DELIVERY INSPECTION |

|

|

|

|

|

|

|

|

|

|

Whenever desirable we furnish and completely machined every detail, or partially machined, unless otherwised specified, however we eill furnish the equipment as cast with particular care to provide not more and not less metal for metal for machining than good machine practice demands. |

|

|

|

|

Your continuous operation will depends upon your choice of best mechanical parts, to meet exacting requirements, our products are cast of selected material, free of blow holes and hard spots, and maintain a surface as smooth as silk and give little frictional resistance. |

|

Our manufacturing procedure undergo several careful inspections and test to insure workmanship consistent with the supreme quality of materials anf carrying out the specification correctly. |